High Velocity Hot Oil Flush

- Decontamination of system piping, coolers, filter housings and reservoirs with turbulent flow and mechanical cleaning meeting API 614 standards

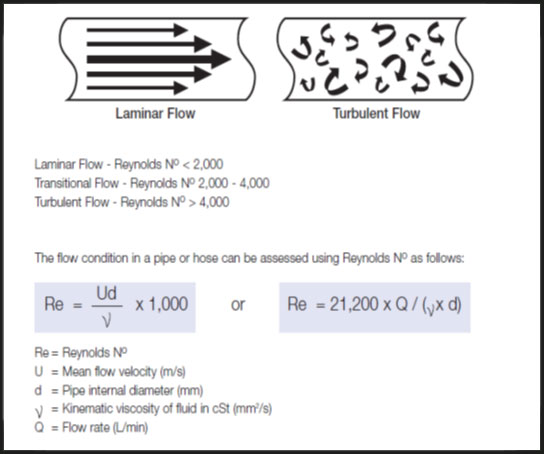

- Generally, most hydraulic lubrication oil systems are designed for "laminar" flow. This calls for a constant operation without cavitation or vibration.

- Efficient flushing, requires turbulent flow to dislodge contaminants deposited on the inside of piping, coolers, housings and reservoirs.